EXPERTS in Steam to Water Heat Exchangers

#1 Top Rated Steam to Water Heat Exchangers

Built for New York

High Efficiency Steam to Water Heat Exchangers engineered for New York's demanding specifications. Complete technical documentation, certified installations, and expert support for engineers and facilities.

NYC Code Compliant

Complete Specification

Expert Installation

Request NY Code-Compliant Steam to Water Heat Exchangers Specs

Building-Ready Submittals • Engineered Steam Heat Exchangers for NY Facilities • Expert Sizing & Specification Review

Trusted by NY engineers, property managers, and contractors for building-compliant steam heat exchanger systems, commissioning support, and complete documentation.

Serving New York for Over 70 Years

Why Adirondack Combustion Technologies for Steam to Water Heat Exchangers ?

Complete Documentation

Full technical specifications, installation manuals, and compliance documentation provided with every quote.

Expert Engineering

Our team understands New York building codes and can specify the exact equipment your facility requires.

Your Trusted Partner

Proudly serving gas engineers, contractors, plant managers, developers, and facilities in New York.

Installation & Support

Certified installation teams, emergency support, and maintenance programs to extend the life of your systems

Top Rated New York Steam to Water Heat Exchangers

Jordan Rivera

Director of Facilities, Stuyvesant Medical Center

We replaced two aging shell‑and‑tube units with a high‑efficiency plate‑and‑frame system. The new exchangers hold temperature within ±2°F even during morning DHW spikes. Submittals were clean, commissioning was thorough, and our BMS integration was seamless. Downtime was under 6 hours per loop with zero disruption to patient care.

Michael Chen

Campus Energy Manager, Metropolitan University (NYC)

Their team right‑sized our steam‑to‑water exchangers for residence halls and science buildings, added N+1 redundancy, and improved our turn‑down control. We’re seeing lower steam consumption and steadier hot water temps across multiple buildings. The documentation made approvals and utility incentives straightforward.

Robert Martinez

Senior Project Manager, Gotham MEP Contractors

From submittals to startup, the process was professional and predictable. Clear P&IDs, valve schedules, and control sequences meant no guesswork on site. Startup hit design temps on the first day, and the owner loved the trend data and alarm mapping. We’ll partner with them again on our next hospital project.

Frequently Asked Questions (FAQs) - Steam to Water Heat Exchangers

A steam to water heat exchanger transfers energy from steam to building hot water for space heating, DHW, labs, and sterilization loops. In NY, they are common in university campuses and hospital central plants that distribute steam but require precisely controlled hot water temperatures by zone.

We model peak and part‑load profiles by application (DHW, hydronic heating, labs), incoming steam conditions, and required ΔT. We then select plate‑and‑frame or shell‑and‑tube units with proper approach temperature, fouling factors, and redundancy (N+1) to maintain uptime for critical facilities.

Plate‑and‑frame excels at high efficiency, compact footprint, and easy maintenance; shell‑and‑tube offers robust performance in high fouling or high pressure/temperature environments. We recommend based on steam quality, water chemistry, cleaning preferences, and lifecycle cost.

Yes. We provide ASME‑stamped equipment, relief sizing, control schematics, and submittals aligned to NY building requirements and healthcare best practices. We coordinate controls integration and documentation to streamline approval and inspection.

Absolutely. We deliver complete technical submittals, P&IDs, controls sequences, and startup/commissioning. Our team validates setpoints, sensors, and safeties to achieve design temperatures, stable control, and documented performance.

We design N+1 redundancy, isolation valving, and bypass piping, specify premium control valves and sensors, and implement alarms/trending. This keeps mission‑critical hot water available during maintenance or unexpected events.

Yes. We provide open protocol (BACnet/Modbus) integration, trending points, and fault/alarm mappings. Our sequences coordinate with existing boilers, steam PRVs, and DHW priority to optimize energy use without sacrificing comfort.

Routine tasks include strainer cleaning, valve calibration, differential pressure checks, and plate inspection/descaling as needed. We set maintenance intervals by water chemistry, duty cycle, and trending data to minimize fouling and downtime.

Our Heating Solutions Power Top Facilities in New York

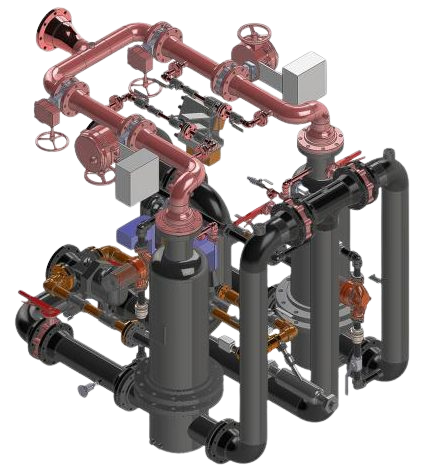

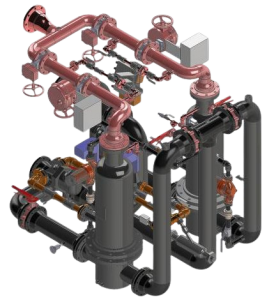

Upstate Medical Center, Syracuse, NY — Maxi-Therm Skid in Tight Mechanical Room

Compact Maxi-Therm skid installed to serve a renovated heart and vascular center where