Adirondack Combustion Technologies

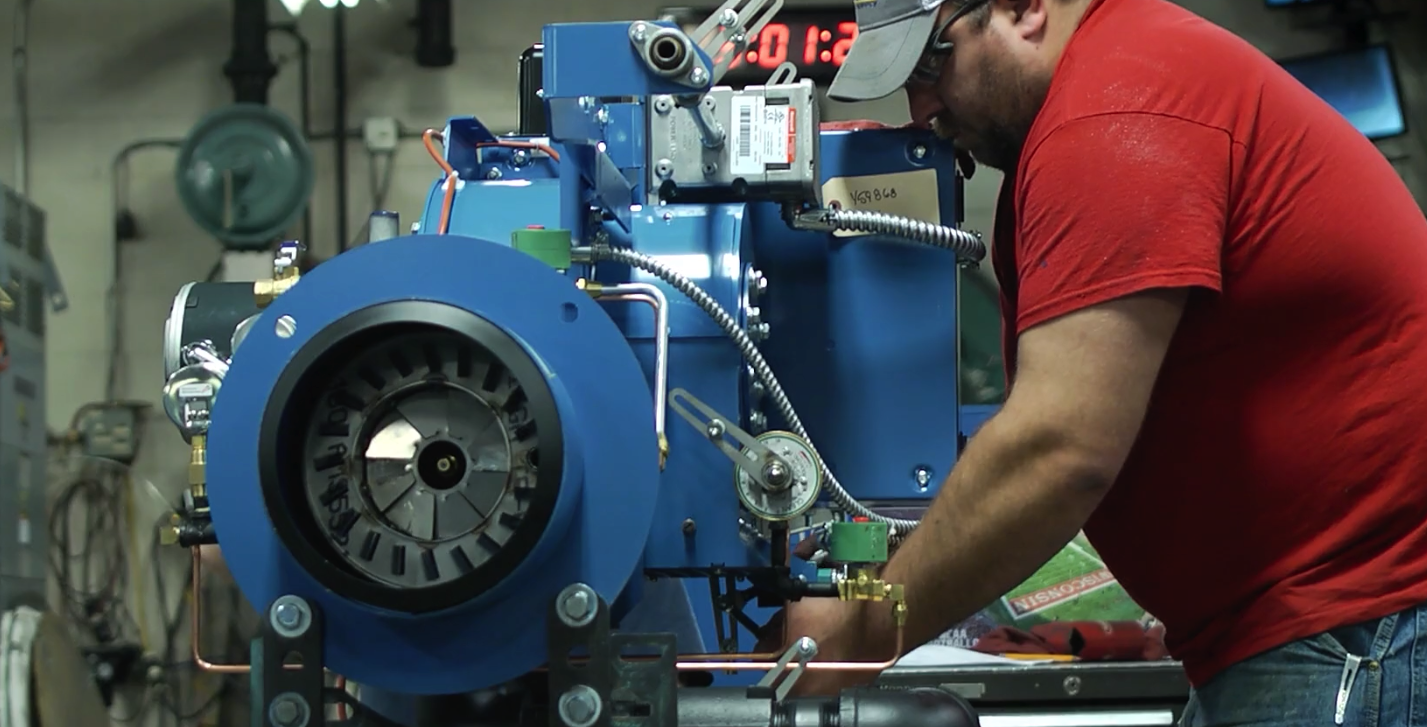

#1 Best Rated Industrial Burner Service & Repair

Proudly serving New York, Vermont, and Massachusetts

28+ Years of Experience Designing and Building Industrial Combustion Systems

Adirondack Combustion Technologies has more than 28 years of experience designing combustion systems for industrial and commercial applications. Our design and engineering team is made up of industry experts who understand burner capabilities. Our team can design burner systems for any requirements.

Experts in Industrial Burners for Safe & Efficient Combustion

Proven Industrial Combustion Solutions & Service

Made for Your Application

We specialize in custom fabricated combustion control systems. Our engineers and technicians design and build these systems in-house using knowledge gained over decades of experience. We are able to design a custom combustion control system for any application.

Industry-Leading Solutions

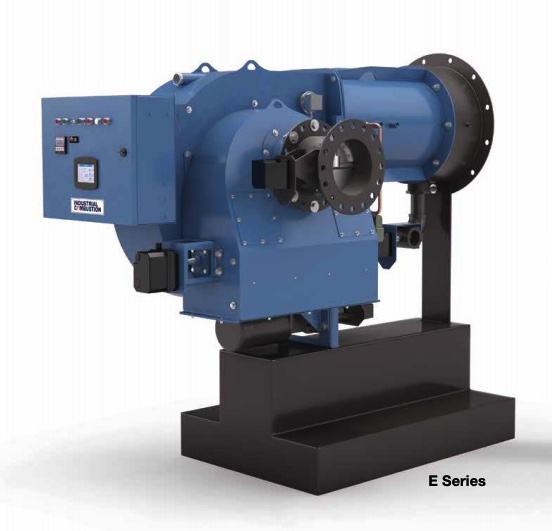

We supply burners from industry-leading manufacturers including Industrial Combustion. Our partners can supply process burners and low NOx burners for nearly any need.

Industrial Combustion has over 70 years of experience designing and manufacturing industrial burners. The company offers a broad product line with 10 different series of burners. They cover a wide range of capacities from 550,000 MBTU/hr to 100,000,000 MBTU/hr. Industrial Combustion burners are available for a range of applications including boilers, water heaters, kilns, and dryers. Low NOx burners are available.

S.T. Johnson Burners has been building burners since 1903. As a leading expert, they offer industry tested and reliable burner designs. S.T. Johnson Burners feature low-emission and out of the box compliance so you can get running quickly. Featured burners include Gun-typed packaged burners (DHF), Ultra Low-Emissions burners (NOXmatic), and Axial-Flow Packaged Burners (FD68).

What is an Industrial Burner?

There is a massive range of industrial burners available today. Each burner is suited to specific needs so it’s critical to have a clear understanding of your requirements before you choose a burner. Our engineering and design team is well-versed in burner requirements and can help ensure your needs are met.

When you provide our team with your requirements, they will perform Computational Fluid Dynamics (CFD) modeling to ensure that optimal heat transfer, efficiency, and burner longevity are achieved. This process will also ensure that all supplied burners are totally compatible with your boiler or furnace in order to achieve ultra-high efficiency.

Our engineers have the expertise needed to ensure maximum burner efficiency in your application. From your requirements, our team can determine the best capacity, turndown, flame geometry, temperature, mounting, and ignition specifications for your needs. We can then recommend the best low NOx burner or process burner for whatever you require.

Common uses for boilers

- Boilers

- Furnaces

- Kilns

- Dryers

- Water Heaters

- Process Equipment

- Welders

- Smelters

Typical end users

- Hospitals

- Universities & Schools

- Residential Buildings

- Food Production Plants

- Factories

- Recycling Plants

- Pharmaceutical Plants

- Metal Production

- Glass Blowing

How Does a Burner Work?

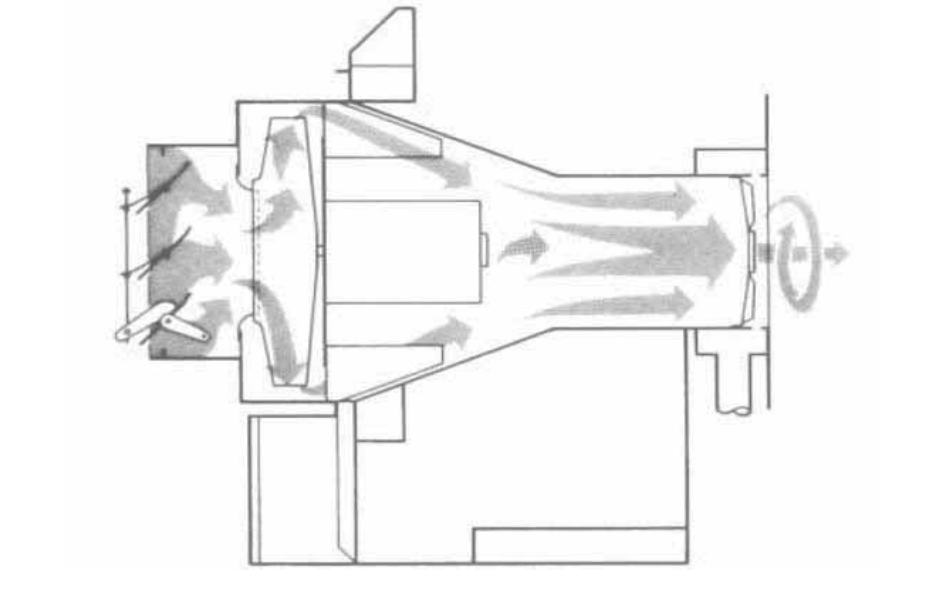

A burner can provide reliable combustion using a wide range of fuels. Common burner fuels include natural gas, oil, LPG, biogas, and duel-fuel. Regardless of which fuel is used, the burner’s main function is to mix the fuel with a set amount of air or oxygen to create controlled combustion.

Industrial burners are available in a wide range of capabilities for any combustion requirements. Different models can produce various flame and heat-release patterns which can often be tuned within the burner’s combustion chamber for specific applications. This can be achieved using a combustion control system.

Cold Air Burners

Hot Air Burners

A hot air burner preheats ambient air coming into the unit using a central heat exchanger. Hot air burners are more efficient than cold air burners because for the same amount of ambient air, they require less fuel to create combustion.

More About Industrial Combustion Burners

Industrial Combustion has over 70 years of experience developing industrial burners. The company was the first to introduce breakthrough features like the air-atomizing system and continues to lead the way in burner innovation.

Industrial Combustion offers a broad product line with 10 different series of burners. They cover a wide range of capacities from 550,000 MBTU/hr to 100,000,000 MBTU/hr.

The Industrial Combustion SBR-30 is a low NOx burner designed for use in firetube and watertube boilers. It is available up to 1,300 hp and can be configured to run on natural gas or #2 oil. The Industrial Combustion D/LND Series covers a wider range of applications including boilers, water heaters, kilns, and dryers. Sizes are available up to 1,000 hp. They can be configured to run on a wide range of fuels including natural gas, #2-6 oil, or a combination. Industrial Combustion XL/LNXL burners are designed for the largest firetube and watertube boiler applications. These burners are available up to 2,200 hp and can run on fuels including natural gas, #2 oil, or a combination.

Let's find the right industrial burner for your project.

Contact us to ask a question or begin a conversation.