Adirondack Combustion Technologies

Best Rated NY Custom Combustion Control Systems

Proudly serving New York, Vermont, and Massachusetts

28+ years of Experience Designing and Building Combustion Control Systems

At Adirondack Combustion Technologies, we are combustion control experts. We have over 28 years of experience serving the North Country, Eastern Massachusetts, and Vermont with combustion control solutions. We offer UL/UL-508 listed controls.

Experts in Industrial Combustion Control Systems for Safe & Efficient Combustion

Proven Industrial Combustion Solutions & Service

Made for Your Application

Real-World Proven Solutions

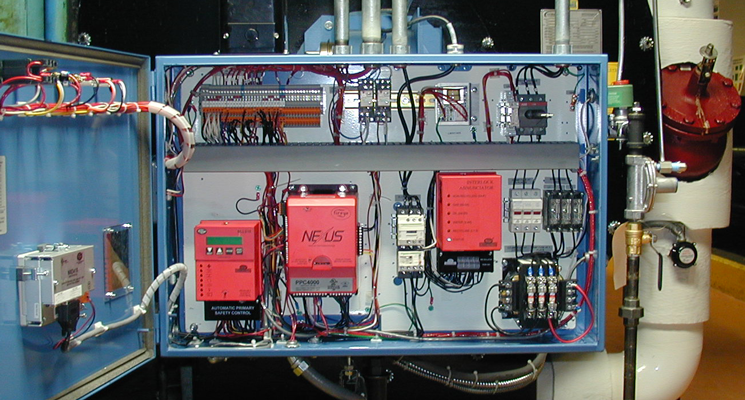

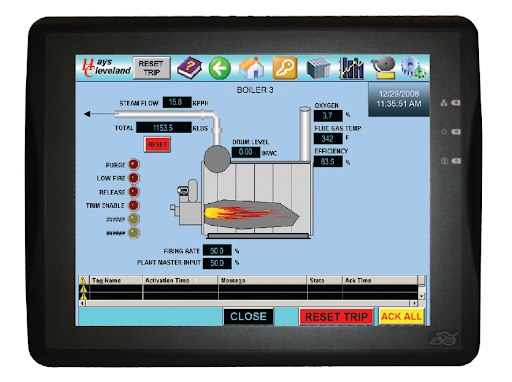

We can also provide proven combustion control solutions from top industry names including Hays Cleveland and Fireye for any application you have.

Hays Cleveland offers a long list of combustion control solutions for any application. The company’s product line covers nearly every aspect of combustion control from burner control and lead/lag sequencing to flame monitoring and burner scanning. The Hays Cleveland UPAC package is the company’s most robust controller, offering almost unlimited control capability for 10 or more devices.

Fireye is a long-standing industry leader with over 90 years of experience producing combustion control solutions. The company offers a wide range of intelligent flame safeguard controls, parallel positioning controls, and burner management systems. The Fireye BurnerLogix full-function controller is one of the company’s primary offerings. It can learn the characteristics of the fuel being burned in order to optimize detection under all conditions.

What is a Combustion Control System?

Combustion control systems encompass all of the electronic systems responsible for controlling a boiler and its combustion cycle. These systems are responsible for determining how much fuel, air, and water are needed inside the boiler at any given time. The combustion control system continuously monitors these variables to maintain peak efficiency.

Combustion control systems always have built-in failsafes to prevent dangerous conditions inside the boiler. Using the proper boiler control system will help your boiler and burner operate at peak efficiency as much as possible.

What is a Burner Management System?

A burner management system is another type of electronic combustion control system that specifically manages the burner itself. While the combustion control system helps the burner and boiler meet peak efficiency by altering combustion variables as needed, the burner management system is focused mainly on safety.

The main purpose of a burner management system is to monitor the flame and manage igniters, burners, and actuators. Its primary functions are to inhibit system startup when safe conditions are not met and monitor the burner during use to detect unsafe conditions. A burner management system generally protects against any unsafe operating conditions in your boiler.

The primary benefit of a combustion control system is increased burner efficiency. A properly setup combustion control system will help to optimize combustion conditions within your equipment at all times. That way, you only use the exact amount of energy you need and minimize stress on your equipment.

At Adirondack Combustion Technologies, we are combustion control experts with decades of experience serving the North Country, Vermont, and Eastern Massachusetts. Our in-house engineers and boiler control technicians are highly experienced with all types of combustion control systems.

We have worked in facilities of all sizes with all manner of different specifications. This experience gives us unique insight – our experts can design a combustion control system for any requirements. Contact our combustion engineers today to discuss your next project.

Typical end users

- Universities

- Schools

- Hospitals

- Manufacturing Plants

- Prisons

- Multi-Unit Residential Buildings

- Commercial Buildings

Factories - Public Housing

- Military Facilities

- Food Production

- Recycling Plants

A combustion control system can be used to fine-tune any aspect of boiler and burner combustion. Using the proper controls with the proper setup will ensure that you get maximum production and efficiency from your burners. At Adirondack Combustion Technologies, we are combustion control experts with the knowledge required to maximize burner performance in all applications.

Your specific combustion control system will depend on your project requirements and the needs of your facility. In general, there are a few common uses for combustion control systems. At ADK Combustion, we are experts in all areas of combustion control systems.

Parallel Positioning

This method is one of the best ways to ensure maximum efficiency in your boiler. A parallel positioning system uses independent actuators for every combustion variable meaning that each variable is controlled to its own exact specifications. These systems allow for highly precise and repeatable fuel/air metering and consumption. This method can provide energy savings up to 10% compared to single point control systems.

Controlling Lead/Lag

This method is used to sequence the operation of multiple boilers at once. It is used to match the load demand to your system’s optimum output. By sequencing your boilers in a specific way, a lead/lag system helps ensure peal efficiency at all times. This also helps reduce cycling and decreases your system maintenance downtime.

Variable Speed Drive

Controlling the speed of your burner motor is critical for reducing your energy costs. A combustion control system can be setup to vary motor speed for only what is needed at any given moment. Instead of the constant 3,600rpm of a typical motor, a variable speed drive system will lower the motor speed when there is less demand. This lowers your electrical costs, allows for quieter operation, and reduces stress on critical motor components.

Adjusting Oxygen Trim

A combustion control system can also continually adjust oxygen trim to ensure peak efficiency. To do this, sensors continuously read the oxygen concentration in the boiler flue gas. If there is too much excess air in the flue gas, the sensor tells the control system to adjust or “trim” the air damper or fuel valve to maintain the most efficient operating conditions. A system like this will constantly optimize your air/fuel ratio to give you the most efficient combustion and lower your energy costs.

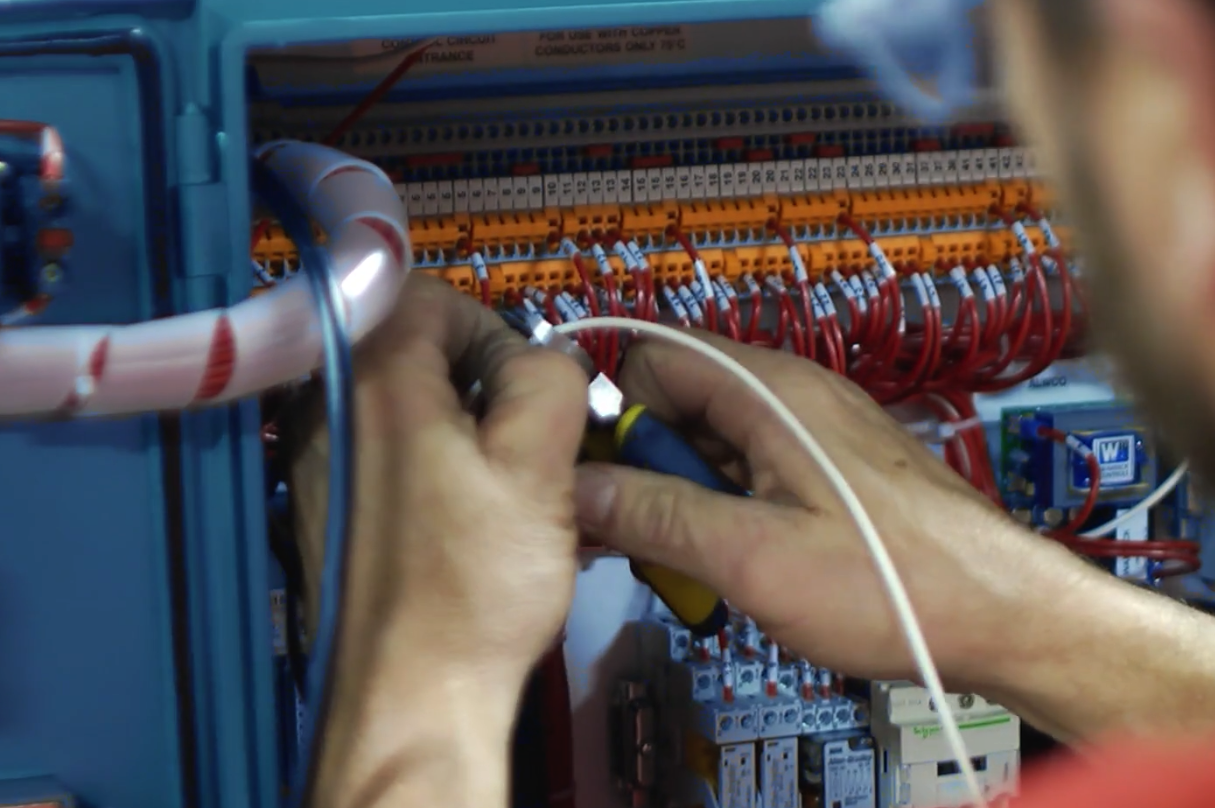

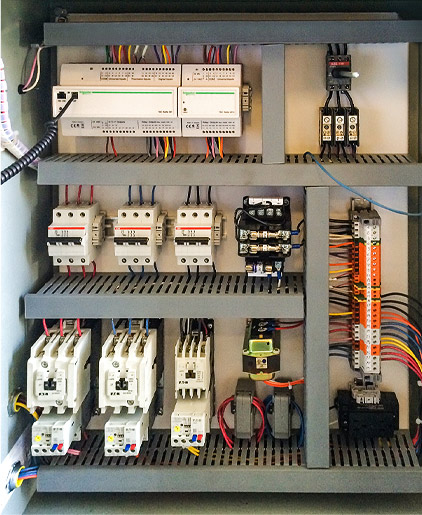

Adirondack Combustion Custom Fabricated Combustion Control Systems

At Adirondack Combustion Technologies, we can also create a custom fabricated combustion control system to any specifications. Our in-house engineering team has decades of combined experience building combustion control systems for all applications.

When you provide us with your specifications, our team will draft a combustion control system design that suits your exact requirements. We will ensure that your combustion system operates at peak efficiency while providing utmost safety and reduced downtime.

At Adirondack Combustion Technologies, we specialize in custom fabricated combustion control systems. Whatever your needs, we are here to meet them. Contact us today to discuss your next combustion project.

Let's build your custom control system solution.

Contact us to ask a question or begin a conversation.