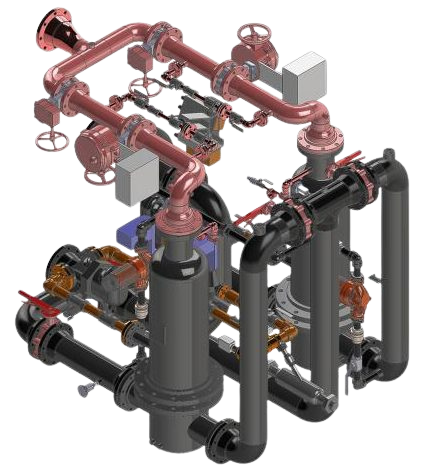

Compact Maxi-Therm skid installed to serve a renovated heart and vascular center where mechanical room space was extremely limited.

Upstate Medical Center in Syracuse, New York renovated part of an existing building to create a new heart and vascular center. The project added critical clinical spaces and support areas without expanding the original footprint, which left very little room for new mechanical equipment. Steam and hot water service remain essential to patient care, comfort, and building operation, but traditional heat exchanger layouts would not fit the available space. Adirondack Combustion Technologies was brought in to provide a compact steam-to-hot-water solution that could deliver the required flow and temperature control within strict dimensional constraints and existing access paths.

Project Overview: Existing System Constraints and Risks

The renovation introduced new clinical loads and higher expectations for temperature stability while the physical space for mechanical equipment stayed tight. Existing infrastructure and access paths limited how large a skid or assembly could be brought into the building.

Key issues included:

- Very limited mechanical room floor area and clearances around new equipment.

- Restricted access routes that required equipment to fit through existing shafts and openings.

- The need to support new heart and vascular center spaces with reliable hot water and heating.

- Risk that oversized or field-assembled systems would delay the project or complicate maintenance.

These constraints created risk around both project execution and long-term operation. The hospital needed a solution that would physically fit, support clinical operations, and avoid future service headaches in a congested mechanical space.

Solution: Selected Equipment and System Design Rationale

To address the space and performance requirements, the team selected a Maxi-Therm Model MCU-350G-30F-15P skid capable of 350 gpm with a 150°F to 180°F temperature range. The skid was engineered and packaged to meet the hospital’s capacity and temperature needs while respecting tight dimensional limits.

The design rationale focused on:

- Using a pre-engineered Maxi-Therm skid with known dimensions (approximately 79 7/16″ high × 66 1/2″ long × 66 3/8″ wide) to verify fit before fabrication.

- Providing 350 gpm capacity with a 150°F to 180°F outlet range to cover the new heart and vascular loads and associated building zones.

- Leveraging a compact skid layout to leave workable clearances for service, valves, and controls within the mechanical room.

- Reducing on-site assembly time by delivering a completed package that could be set in place and connected.

The packaged approach gave the hospital a clear path to meeting performance requirements without redesigning the mechanical space or compromising access.

Consultative Execution: Engineering Approach and Coordination

Adirondack Combustion Technologies acted as more than an equipment supplier, helping the project team plan how the Maxi-Therm skid would be moved into the building and integrated with existing infrastructure.

Key elements of the approach included:

- Reviewing architectural and structural limitations, including the airway shaft used to bring the skid into the building.

- Coordinating with engineers and contractors on piping, valving, and control tie-ins to the existing steam and hot water systems.

- Planning lift, rigging, and movement steps so the completed skid could be lowered through the airway shaft and rolled into final position.

- Supporting commissioning activities to confirm flow, temperature, and control sequences under clinical operating conditions.

By working closely with the design and construction teams, ACT helped ensure that the solution was practical to install and service, not just technically correct on paper.

Results & Operational Impact: Post-Installation Performance

Once installed and commissioned, the Maxi-Therm MCU-350G-30F-15P skid provided the hospital with a stable, compact steam-to-hot-water interface for the renovated heart and vascular center.

Observed improvements include:

- Reliable delivery of hot water and heating within the 150°F to 180°F range required by the new clinical and support spaces.

- Efficient use of limited mechanical room area while maintaining workable clearances around the skid.

- Reduced on-site assembly and installation time thanks to the pre-packaged design.

- Improved confidence that future maintenance can be performed without major disruption to adjacent equipment.

These outcomes support both patient comfort and facility operations, while giving the hospital a clear, documented solution that fits the physical constraints of the building.

Why This Matters for Similar Facilities and Applications

Hospitals, medical centers, and other healthcare facilities in New York often renovate existing buildings to add new clinical services without adding new mechanical space. In these projects, standard equipment footprints or field-built systems can quickly run into space, access, and phasing challenges.

Projects like the Upstate Medical Center installation show that facilities can:

- Use compact, pre-engineered steam-to-hot-water skids to serve new clinical programs in constrained mechanical rooms.

- Plan equipment movement and placement around existing shafts and access routes.

- Balance capacity and temperature requirements with long-term serviceability in tight spaces.

Adirondack Combustion Technologies supports steam and combustion projects across New York State, helping facilities match packaged solutions to real-world space and access constraints.

Request a Free Specification Quote

Commercial, institutional, and healthcare facilities in New York can request a no-obligation specification review to evaluate steam and hot water solutions for new or renovated spaces. The review can cover loads, code requirements, venting and access constraints, and existing infrastructure so that the proposed approach fits both clinical needs and the physical limits of the building.