Top Rated Maxi-Therm Heat Exchangers – High-Efficiency DHW & Heating Systems for Upstate NY Mechanical Engineers

Steam-to-liquid heat exchangers

Turn Steam into Savings

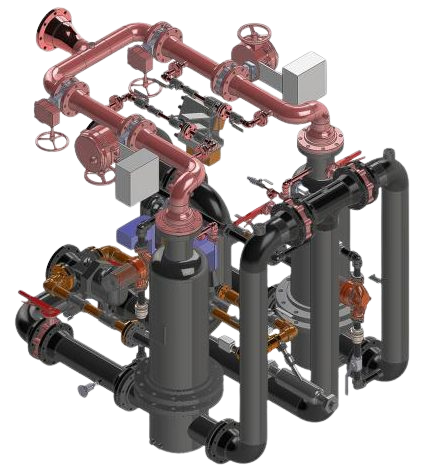

Compact, Fully Packaged

Steam-to-Water Solutions for Schools, Hospitals & Industrial Facilities

If you design, operate, or retrofit commercial or institutional buildings across Upstate New York, you know steam distribution systems are everywhere—but traditional heat exchangers waste energy, occupy large spaces, and require frequent maintenance.

Maxi-Therm changes that. Their complete steam-to-water packaged systems deliver instantaneous hot water or hydronic heating with up to 95% energy efficiency, no flash tank, and a small footprint.

With vertical flooded heat exchangers, high turndown modulating controls, and condensate subcooling, Maxi-Therm’s systems maximize energy recovery, reduce operating costs, and deliver reliable performance even under fluctuating loads.

Now available through Adirondack Combustion Technologies, your authorized Maxi-Therm representative for Upstate New York.

Ready to modernize your steam system?

Contact Adirondack Combustion Technologies to:

- Request a no-obligation heat load analysis and quote

- Access Maxi-Therm submittals, drawings, and BIM/Revit files

- Schedule onsite evaluation or startup assistance

📞 (518) 283-8295 📧 info@adirondackcombustion.com

P-K Duration Key Benefits

- Instantaneous Steam-to-Water Heating Eliminates storage tanks while providing consistent domestic or hydronic hot water on demand Perfect for healthcare, education, and hospitality applications.

- Up to 95% Energy Efficiency Subcools condensate to recover every Btu possible Less wasted energy equals lower fuel costs and reduced carbon footprint.

- Fully Packaged & Factory Tested Delivered pre-piped, pre-wired, and pre-tested Just connect steam, condensate, and water lines — reducing installation time and on-site labor costs.

- Vertical Flooded Heat Exchanger Design Compact, self-draining, and resistant to scaling and thermal stress Ideal for retrofits or tight mechanical spaces.

- No Flash Tank or Steam Trap Simplifies your plant layout Virtually eliminates maintenance headaches and water hammer issues.

- Compact Footprint Freestanding design Fits tight basements, utility corridors, and mechanical rooms.

- Smart Controls Integration Compatible with BAS via Modbus, BACnet, or LonWorks Easy monitoring and optimization of your system.

Upgrade your steam system to a high-efficiency Maxi-Therm unit today.

✅Free system review & sizing assistance

✅ Local installation & service team

✅ Fast turnaround & reliable support

📞 (518) 283-8295

📧 info@adirondackcombustion.com

How It Works (Application Overview)

The Maxi-Therm system takes high-pressure steam and passes it through a vertical flooded heat exchanger, transferring energy into the domestic or heating water loop.

Unlike traditional shell-and-tube or plate heat exchangers, the Maxi-Therm unit uses a flooded design where condensate and steam remain in equilibrium, eliminating the need for control valves or flash tanks.

The Result:

- Stable temperature control (±2°F) even with load fluctuations

- Improved condensate management with subcooling

- Simple, safe, and efficient installation and operation

Applications Include:

- Universities & schools

- Hospitals & labs

- Food and beverage plants

- Government & industrial facilities

Why Engineers & Facilities Choose Maxi-Therm

By selecting the Duration III, you also simplify commissioning, piping design and retrofit planning because of its compact form, minimal connections and BAS integration. For multiple unit installations, you can locate units side-by-side, pipe in parallel and meet higher capacity demands without sacrificing footprint. Bundle with an Accardi Building Automation System to get real-time performance monitoring, reducing manual oversight for mechanical contractors in NYC who maintain multiple sites.

- Reduced Lifecycle Cost Fewer moving parts, no traps, and simplified maintenance Lower operating costs and extended equipment longevity.

- Energy Savings Recovers heat from condensate Reduce boiler fuel usage by up to 15%.

- Code-Compliant Design Meets ASME and local Upstate NY mechanical code requirements Designed for compliance and peace of mind.

- Small Footprint Compact, space-saving design Frees up valuable mechanical room space.

- Ease of Integration Seamlessly ties into existing systems Works with existing steam systems and BAS networks.

- Factory Support & Local Service Complete installation and ongoing support Adirondack Combustion provides full startup, training, and warranty support across Upstate NY.

Ready to modernize your steam system?

Contact Adirondack Combustion Technologies to:

- Request a no-obligation heat load analysis and quote

- Access Maxi-Therm submittals, drawings, and BIM/Revit files

- Schedule onsite evaluation or startup assistance

📞 (518) 283-8295

📧 info@adirondackcombustion.com

Why Choose Adirondack Combustion

- Local ExpertiseServing mechanical engineers and contractors across Albany, Syracuse, Rochester, and Buffalo for over 40 years.

- Factory-CertifiedAuthorized Maxi-Therm sales and service partner with full technical support.

- Turnkey SolutionsFrom system selection to startup and ongoing maintenance.

- On-Site SupportField engineers available for commissioning, troubleshooting, and operator training.

- Fast Lead TimesLocal coordination ensures quick delivery and responsive support.

Frequently Asked Questions (FAQs)

Maxi-Therm’s vertical flooded design eliminates control valves and flash tanks, providing stable temperature control, higher efficiency, and simpler maintenance.

Yes, Maxi-Therm systems integrate easily with existing steam infrastructure — ideal for modernization projects in Upstate NY schools, hospitals, and industrial sites.

By subcooling condensate before discharge, recovering latent heat that’s normally lost, and using precise modulating control for real-time energy optimization.

Minimal. The design eliminates traps and control valves, reducing service points. Periodic cleaning and sensor calibration maintain peak performance.

Yes, Maxi-Therm systems meet ASME and NYS code standards and are widely approved for commercial and institutional projects statewide.

Yes. Dual-service configurations are available for buildings needing both domestic hot water and space heating.

Adirondack Combustion offers fast local quoting and coordinates with Maxi-Therm’s manufacturing facility for rapid delivery timelines.

Our team of experts is ready to help you specify, size, and install the perfect Maxi-Therm solution for your facility.

📞 (518) 283-8295

📧 info@adirondackcombustion.com