Adirondack Combustion Technologies

#1 Top-Rated Industrial Hot Water Boiler Service & Repair

Proudly serving New York, Vermont, and Massachusetts

Over 28 Years of Experience in Boiler Service and Repair

Adirondack Combustion Technologies has more than 28 years of experience working with commercial heating installations of all sizes. We are a complete lifecycle boiler solutions provider, offering a range of boiler services including cleaning and maintenance for the entire life of your equipment.

Experts in Hot Water and Steam Boilers

Proven Industrial Combustion Solutions & Service

Certified Experts

Top Manufacturer Representative

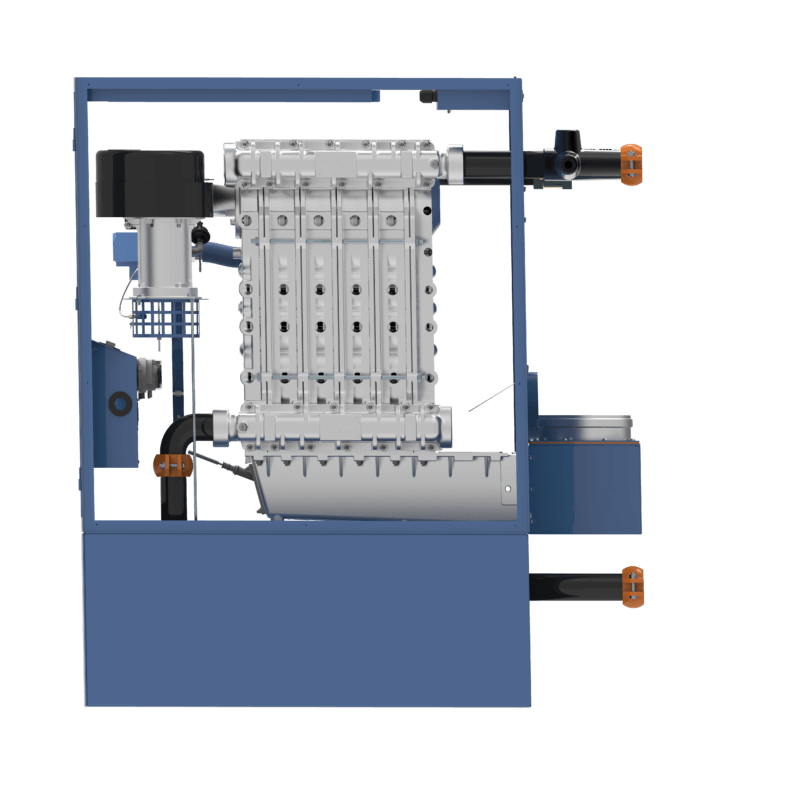

Patterson-Kelley boilers are highly efficient and compact. Each one can fit through a standard commercial doorway for easier installation. PK boilers also offer extremely low emissions thanks to low NOx burners and smart boiler management systems.

Rentech specializes in custom boilers for steam capacities up to 500,000 lbs/hr, 1800 psig and 1000°F. Every Rentech boiler is custom-designed for your unique project requirements. They offer drastically reduced emissions and are perfect for ultra-low NOx applications.

L.E.S. offers a range of pre-packaged and custom-designed boiler solutions for hot water and steam applications. Unique features like a submerged combustion chamber design, forced-draft burners, and custom bent steel turbulators provide up to 83% efficiency.

Precision Boilers is known for its ultra-compact electric boilers. These boilers are extremely compact and require no vent stack or breeching so install costs are lower. Precision Boilers also offers more traditional watertube and firetube boilers. Low NOx configurations are available as low as sub-9ppm.

E-Tech focuses primarily on capturing waste heat for use in heating applications. This method is highly efficient and proven to save on energy costs. The company offers firetube and watertube waste heat boilers.

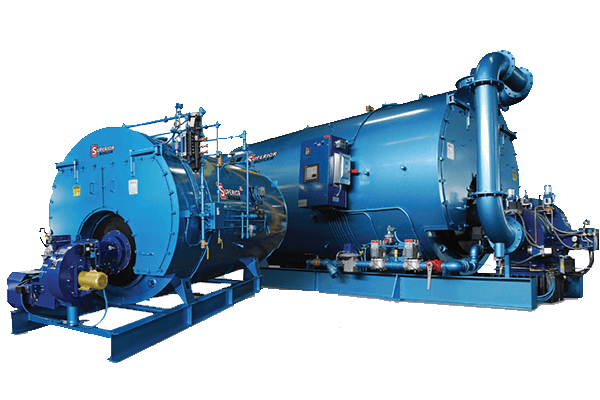

Superior Boiler Works is the world’s leading manufacturer of scotch marine firetube boilers and high-efficiency condensing boilers. Superior Boiler also supplies a wide range of boiler room equipment for process steam, hot water, and waste heat recovery.

Novatherm is a leading manufacturer of highly efficient steam and hot water boilers. The company offers a range of traditional watertube and firetube boilers as well as electric boilers which offer greater than 99% efficiency.

Maxi Therm specializes in a factory assembled, fully integrated flooded heat exchanger. Ideal for building heat and domestic use. Features include small physical footprint, few moving parts, customizable configuration, and single source responsibility.

What is a Boiler?

Adirondack Combustion Technologies is the leading heating equipment provider in Upstate NY and Vermont. We have more than 28 years of experience providing the North Country with expert boiler service, maintenance, and installation.

We are boiler experts. We have experience working in schools, universities, hospitals, and government facilities of all sizes. Our team of experts understands the unique requirements of large-scale commercial heating projects. We will work with you to create a plan that is right for your project.

Common uses for boilers

- Commercial heating

- Residential heating

- Paper/pulp production

- Electricity generation

- Food processing

Typical end users

- Schools

- Universities

- Hospitals

- Manufacturing & Processing Plants

- Factories

- Breweries

- Military Facilities

- Housing Facilities

- Prisons

How Does a Boiler Work?

Hot water boilers and steam boilers are the two main types of boilers. Both heat water for use in heating systems, but the way they go about this is a bit different.

In a hot water boiler, the goal is to raise the water temperature to a level just under its boiling point. In hot water boiler systems, the water itself is then pumped through the heating system to provide radiant heat.

In a steam boiler, the goal is to actually boil the water and create steam. The hot steam is then used in the heating system to provide radiant heat. In general, steam boilers require more energy to create steam but use less energy to circulate the steam through the system.

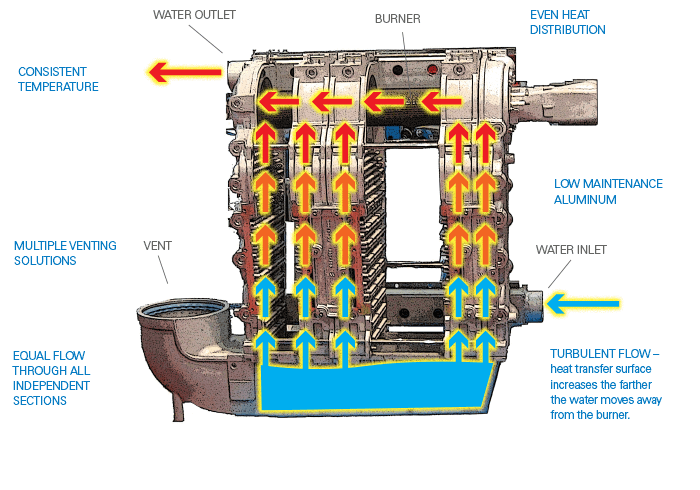

There are two main designs found in today’s commercial boilers: firetube and watertube. This refers to the design of the boiler’s internal heating elements.

In a firetube boiler, combustion takes place inside tubes within the boiler. The tubes run through a large water tank and are completely surrounded by water. Heat is transferred into the water through the walls of the tubes.

Firetube boilers are generally less expensive because they are simpler in design and easier to produce, but they are limited to low and medium pressure applications.

Watertube boilers have a similar yet opposite design. In these boilers, tubes filled with water run through a large combustion chamber. This design offers high thermal efficiency, but can be more costly. Water quality can also have an impact on watertube boiler performance and water filtering may be required in the feedwater system.

Regular maintenance and service can extend the life of your boiler.

Why regular maintenance and service for your boiler is important?

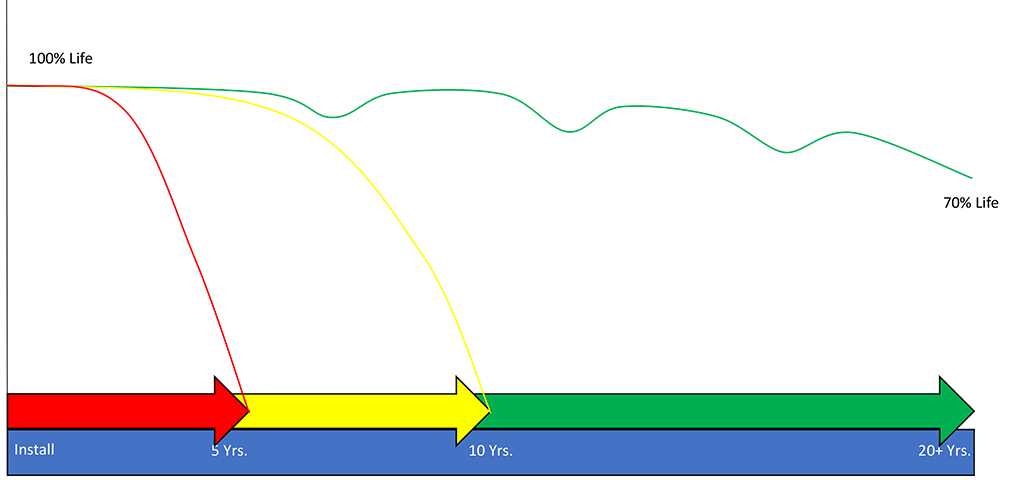

The graph below shows 3 scenarios of a boiler in various stages of maintenance. Curved lines represent the boiler’s remaining life depending on the service performed. As you can see, our complete lifecycle advantage can extend the life of your boiler over 4x!

Boiler Lifecycle Preventive Maintenance Scenarios

Scenario 1 – Complete Neglect

Boiler is installed, never started up properly, and no annual preventive maintenance is ever performed.

Life Expectancy: 5 Years

Scenario 2 – Inconsistent Maintenance

The boiler is installed and started up properly. However, preventive maintenance is not prioritized after the first 5 years.

Life Expectancy: 10 Years

Scenario 3 – Routine Maintenance

The boiler is installed and started up properly. Preventive maintenance is a priority every single year.

Life Expectancy: 20 Years

Let's find the right hot water boiler for your project.

Contact us to ask a question or begin a conversation.