Adirondack Combustion Technologies

Experts in Boilers, Domestic Water Heating, and Control Solutions

Over 28 Years of Experience

Proven Boiler & Combustion Control Solutions

Adirondack Combustion Technologies (ACT) has been the leading combustion solutions provider in NY, Massachusetts, and Vermont for over 28 years. ACT can provide a wide range of boiler service and combustion products for your application. Let our experts handle your next project.

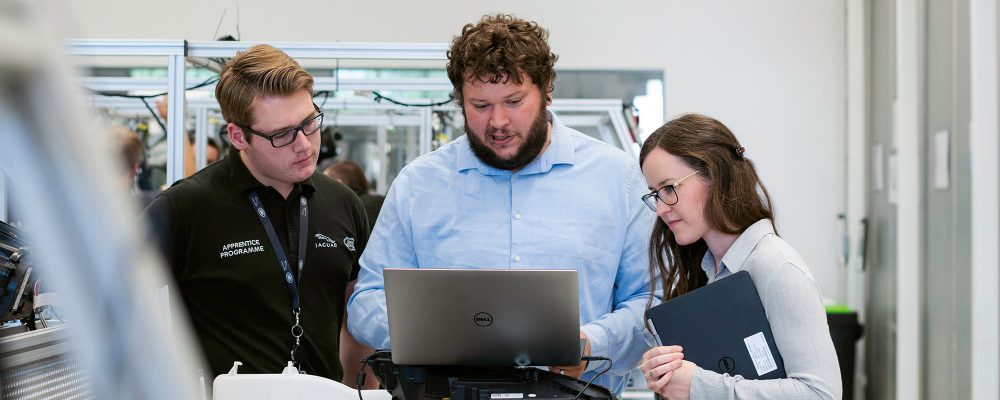

We have an in-house team of combustion engineers and technicians with decades of combined industry experience. Our team can design a boiler or burner system to meet your exact specifications. Additionally, our team can build custom control system solutions.

Our Combustion Solutions and Services

- Patterson-Kelly Water Heaters & Boilers

- Precision Boilers Water Heaters & Boilers

- E-Tech Heat Recovery Systems

- Superior Boiler Works Boilers

- Rentech Boilers

- L.E.S Boilers

- Custom Fabricated Combustion Controls

- Hays Cleveland Combustion Controls

- Fireye Combustion Controls

- Maxi Therm Hot Water Heaters

- Industrial Combustion Burners

- Heat Exchangers

- Annual Cleaning & Maintenance

- Boiler Opening & Closing

- 24/7 Emergency Service

- Boiler & Water Heater Repair

- Boiler Parts & Accessories

- Domestic Water Heating

Commercial Hot Water & Steam Boilers

Industry’s Best Boiler Solutions

Adirondack Combustion Technologies works with industry-leading boiler manufacturers including Patterson-Kelley, Rentech, L.E.S, Precision Boilers, E-Tech Heat Recovery Systems, Superior Boiler Works, and Novatherm.

Patterson-Kelley boiler are compact and efficient with low NOx emissions.

Rentech boilers are custom-designed for every project and are perfect for ultra-low NOx applications.

Precision Boilers is known for its extremely compact and efficient electric boilers.

L.E.S. boilers offer unique features like a submerged combustion chamber design and custom bent steel turbulators.

E-Tech specializes in waste heat recovery boilers which maximize your energy savings.

Superior Boiler Works is the world-leader in scotch marine firetube boilers and high-efficiency condensing boilers.

Novatherm is known for its eVolta electric boilers, offering nearly 100% efficiency.

Industrial Steam Boilers specializes in packaged boilers and field erected boilers built to ASME, UL, CSD-1 and ASHRAE standards compliant with the latest NYC building codes.

Maxi Therm manufactures highly efficient steam water heaters. Each one is built using a vertical flood design which provides at least 5% energy savings over other designs.

Industrial Steam manufactures highly efficient pressurized and atmospheric deaerators designed to extend the life of your boilers.

Boilers & Building Heating

Adirondack Combustion Technologies works leading providers such as Industrial Combustion to supply high-quality industrial burners for a wide range of applications.

Industry Experts

Adirondack Combustion Technologies (ACT) has been the leader in Boilers, Domestic Hot Water Systems, and Custom Control Systems. Servicing industrial facilities in New York, Vermont, and Massachusetts for over 28 years.

Complete Solutions

Our team can customize any solution to meet your safety, efficiency, and overall requirements. We deliver complete solutions. We carry top rater boilers, water tanks, water pumps, deaerator, exchangers, combustion , and control systems for the project.

Commercial Hot Water Heaters

Reliable & Responsive Hot Water Delivery

Adirondack Combustion is proud to supply commercial hot water heaters from Patterson-Kelley, Precision Boilers, and Maxi Therm.

Patterson-Kelley offers both direct and indirect water heaters in tank and tankless configurations. Each one has a small footprint that can easily fit through a standard commercial doorway. PK water heaters also offer excellent efficiency up to 97% on select models.

Precision Boilers specializes in electric and fuel-fired water heaters for the most demanding commercial and industrial applications. They are available in 125 psi and 150 psi design pressures and can achieve temperatures up to 250°F. The largest models are available with storage tanks up to 4,000 gallons.

Maxi Therm is known for its unique and highly efficient steam water heaters. Each one is custom-built to your exact project specifications. Maxi Therm water heaters use a vertical flood design, providing 5% or more energy savings over other configurations. They are highly flexible and can be built using a range of materials.

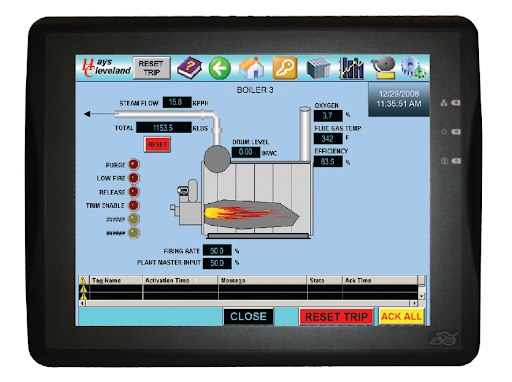

Custom Combustion Control Systems

ADK Combustion specializes in combustion control systems. We supply combustion controls from Hays Cleveland and Fireye. Additionally, our biggest strength is our ability to design and build custom combustion control systems. Our technicians can build and program a custom control solution for any application.

Hays Cleveland

Hays Cleveland offers a broad catalog of combustion control solutions, covering nearly every aspect of combustion control and burner management. Solutions are available for burner control, draft control, lead/lag sequencing, flame monitoring, and much more.

Fireye

In-House Custom Solutions

Adirondack Combustion in-house custom combustion control systems can be built to any specifications. Our technicians are experts in combustion control system design and programming.

Ask us about our Allen-Bradley and other PLC based platforms. Let us build a custom solution that meets your requirements.

Why Choose Adirondack Combustion Technologies?

28+ Years of Experience

Adirondack Combustion Technologies serves all of the North Country region including Eastern Upstate New York, Vermont, and Massachusetts. We have more than 28 years of experience providing expert combustion solutions and service throughout these areas.

Custom Solutions

We Work with Top Manufacturers

We work with top names in the industry including Patterson-Kelley, Rentech, Precision Boilers, Superior Boiler Works, Novatherm, Allen-Bradley, Industrial Combustion, Industrial Steam Supply, Maxi Therm, Hays Cleveland, and Fireye.

As industry experts, we also service brands from other suppliers including: Cleaver Brooks, Camus, Hurst, Fulton, Dietrich, Absolute Boiler, Lochinvar, RBI, Viessmann, Larrs, Buderus, Riello, AERCO, Unilux, and Volcano.

Expert Boiler Service & Repair

Factory-Trained Service Technicians & 24/7 Emergency Service

Adirondack Combustion Technologies also offers service and support for the full lifecycle of your equipment. We can support all of the equipment we supply with onsite repair, cleaning and maintenance services. This is one of our biggest strengths.

We can provide a wide range of aftermarket services for all of our equipment including boiler opening/closing, boiler and water heater repair, equipment inspection, annual service, and boiler cleaning. Our boiler and burner service technicians can come onsite to your facility in order to keep your equipment running at peak performance.

We also offer 24/7 emergency service for all of our equipment. Our service teams will respond quickly in order to reduce downtime and avoid service disruption. We can have a technician onsite at your location anywhere in Upstate NY, Massachusetts, and Vermont.

Why regular maintenance and service for your boiler is important?

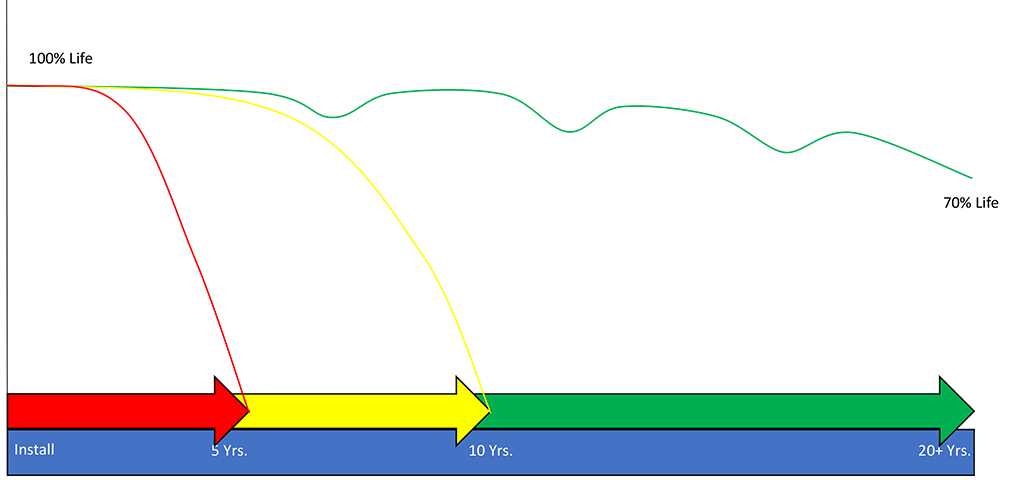

The graph below shows 3 scenarios of a boiler in various stages of maintenance. Curved lines represent the boiler’s remaining life depending on the service performed. As you can see, the ICA complete lifecycle advantage can extend the life of your boiler over 4x!

Boiler Lifecycle Preventive Maintenance Scenarios

Scenario 1 – Complete Neglect

Boiler is installed, never started up properly, and no annual preventive maintenance is ever performed.

Life Expectancy: 5 Years

Scenario 2 – Inconsistent Maintenance

The boiler is installed and started up properly. However, preventive maintenance is not prioritized after the first 5 years.

Life Expectancy: 10 Years

Scenario 3 – Routine Maintenance

The boiler is installed and started up properly. Preventive maintenance is a priority every single year.

Life Expectancy: 20 Years

Let's find the right solution for your application.

Call or Email Us to Start a Conversation About Your Hot Water & Steam Application.